【Industry Application】 Tech-Empowered Peak Performance: Kexcelled Supports Tongji SuperPower in RoboMaster 2025

When "Extreme Competition" Meets "Agile Manufacturing"

In the arena of the RoboMaster University League (RMUC), success is determined by more than just AI algorithms and tactical engineering—it is an "arms race" of material science and manufacturing efficiency.

Team Profile: Tongji University SuperPower Robotics Team

Founded in October 2014, SuperPower is the most interdisciplinary team on campus. With members spanning mechanical engineering, electronics, computer science, and automation, the team has competed in the DJI RoboMaster series for ten consecutive years.

In the 2025 season, SuperPower achieved remarkable results:

2nd Runner-up: RoboMaster League (Shanghai Station)

Champions: Eastern Region

Top 8: National Finals

The "Ceiling" of Traditional Craftsmanship: Four Pain Points in Combat

High-intensity robot combat demands parts that can withstand violent collisions, high-frequency vibrations, and complex environments. Traditional injection molding and CNC machining revealed significant drawbacks during the rapid R&D phase:

Lagging R&D Cycles: Traditional mold development cannot keep pace with the rapid technical iterations required mid-season.

Limited Design Freedom: Complex geometric structures and custom-sized parts are difficult to achieve through subtractive manufacturing (CNC).

The Strength vs. Brittleness Paradox: Common materials often suffer from fatigue or fracture under extreme impact, compromising core module reliability.

Weight Reduction Pressure: Mobility is the key to victory, yet traditional parts often sacrifice weight advantages to maintain structural integrity.

Kexcelled Solution: High-Performance Materials for a Performance Leap

To meet the customized needs of the SuperPower team, Kexcelled provided an FDM printing solution centered on THE K8™ PA CF (Carbon Fiber Reinforced Nylon) and TPU 95A (Flexible Material).

The Peak of Rigidity and Heat Resistance: THE K8™ PA CF Applications

The PA CF series has become the ideal alternative to traditional metal and expensive CNC parts due to its superior strength, stiffness, and thermal stability.

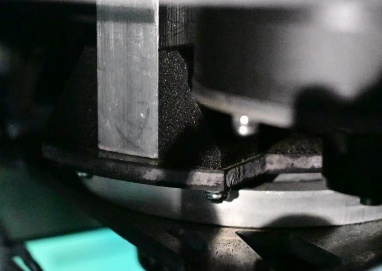

Ammo Chain Sidewalls: Utilizing FDM’s integrated molding capability to replace traditional flat cutting. This allows for complex 3D structures with embedded bearings, significantly reducing friction and increasing feeding efficiency.

Ammo Funnels & Infantry Links: Upgrading from resin and nylon tubes to PA CF solved issues regarding pressure deformation and cracking, vastly improving load-bearing capacity.

Tube Clamps: For the carbon tube adapters on drone propeller guards, the lightweight FDM structures effectively absorb impact energy, protecting the core carbon tubes during collisions.

Aluminum Square Tube Vertical Connectors: While traditional aluminum parts are prone to fatigue fractures, the PA CF printed parts reduced costs by over 60% and enhanced long-term reliability through superior material toughness.

Energy Absorption in Extreme Environments: TPU Elastic Solutions

Dart System: By upgrading from PLA to TPU 95A, the components maintain excellent toughness even in low-temperature environments, solving the issue of shortened service life caused by cold-weather brittleness.

Field Feedback from the Team

"After switching to Kexcelled's high-performance printing materials, our components became easier to install and withstood the rigors of high-intensity competition. The strength of PA CF allowed us to boldly experiment with complex lightweight structures, while the TPU materials significantly improved the durability of our darts and protective gear. This isn't just a material upgrade; it’s a revolution in our R&D model."

— Technical Lead, SuperPower Team

Conclusion: Exploring the Infinite Possibilities of 3D Printing

The success of the SuperPower team proves the immense potential of high-performance FDM technology in high-precision, high-strength, lightweight design, and rapid iteration.

From the competitive arena to the industrial floor, Kexcelled remains committed to driving the deep application of 3D printing in aerospace, automotive manufacturing, and cutting-edge robotics. We welcome more innovators to join us in igniting the sparks of technological progress.