Understanding Kexcelled: How We Name, Classify, and Engineer Our Filaments

When choosing 3D printing filament, users often face two key questions:

What does this product name mean? and Which filament best fits my printer and application?

To simplify this decision, we developed the K’s system — a structured way to name, classify, and optimize filaments based on material, performance level, and application needs.

Product Naming: THE K? + Material + Feature

Our filament naming follows a clear and consistent format:

THE K?™ + Material + Feature

This structure allows users to instantly understand a filament’s performance tier, base material, and surface characteristics.

Example: THE K5™ PLA M

One of our best-selling products, THE K5™ PLA M, demonstrates this naming logic:

PLA indicates the base material (Polylactic Acid)

M stands for Matte, describing its low-gloss surface finish

In other words, this filament is PLA-based with a matte texture, designed for users who want both easy printing and a refined, premium appearance.

Three Performance Tiers: Matching Filament to Printer Capability

Your Golden Rule for Successful Printing:

Material Performance × Printer Capability = Print Success

K’s filaments are categorized into three major performance tiers, based on printability, mechanical strength, and thermal resistance.

K3–K6: Entry to Standard Tier — optimized for ease of printing and everyday applications

K7–K9: Professional Tier — balanced performance for functional and advanced prints

K10–K12: Enterprise Tier — engineered for high-strength, high-temperature, and demanding industrial applications

| Tier | Compatible Printers | Performance Positioning |

|---|---|---|

|

Basic (K3/K5/K6) |

Universal Compatibility (Consumer / Professional / Industrial) |

Beginner Friendly Easy to mold, High cost-performance |

|

Professional (K7/K8/K9) |

Advanced Equipment (Some Consumer / Professional) |

Durable & Robust Mechanical property upgrade |

|

Enterprise (K10/K11/K12) |

High-end Equipment (Professional / Industrial) |

Peak Performance Heat resistant, High strength |

The higher the K-level, the stronger the material performance and the more advanced the potential applications — from decorative prints to structural, heat-resistant, and engineering-grade parts.

This tier system helps users find the ideal match between filament complexity and their printer’s technical capability, reducing trial-and-error and improving print success rates.

Six Major Filament Series: The “Avengers” of Materials

Think of our filament lineup as a team of specialists — each series designed to excel in specific performance domains such as mechanical strength, thermal resistance, and surface aesthetics.

We categorize K’s filaments into six major series, forming a complete ecosystem for different printing needs.

1. General

2. Aesthetic

3. Functional

4. Flexible

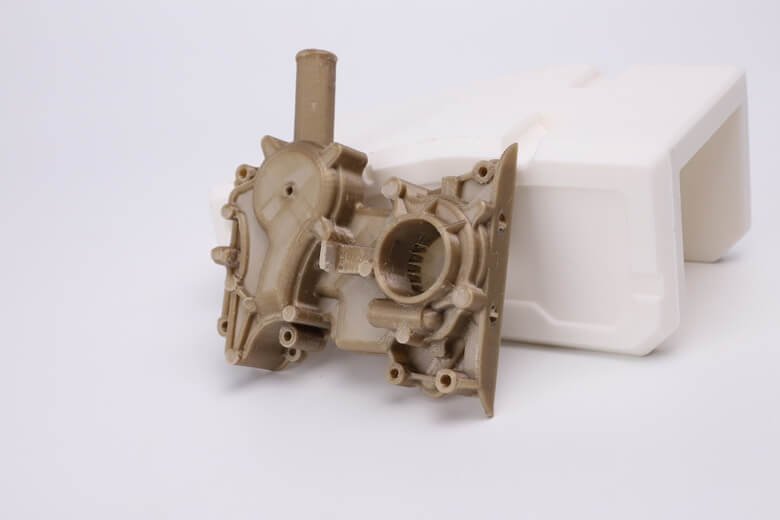

5. Engineering

6. Special Engineering

Why the K’s System Matters

The K’s system is designed to help makers, engineers, and businesses:

Quickly understand material performance levels

Choose filaments that match printer capabilities

Reduce failed prints and wasted material

Scale from hobbyist projects to industrial applications

By combining clear naming, tiered performance levels, and material series classification, K’s filaments create a smarter, more predictable 3D printing experience.

Coming Next: A Deeper Dive into Each Series

This article introduced the K’s definition, but this is just the beginning.

In future posts, we’ll explore the remaining filament series — highlighting their strengths, ideal applications, and performance advantages.

Stay tuned as we continue building the ultimate filament selection guide.